Automated X-ray Computed Tomography (CT) systems are indispensable in industry. They verify whether products meet quality requirements. However, these systems can deteriorate or even fail without being detected, with potentially major consequences such as rejecting good products or, worse, approving defective ones. Sioux Technologies has developed a groundbreaking solution: the Condition Monitoring X-ray system, known as CMX. It enables 100 per cent inspection and can even identify the underlying causes of measurement errors.

X-ray CT systems make it possible to inspect products quickly and accurately. They create hundreds of X-ray images and combine them into a 3D image to reveal defects. This technology is used in many manufacturing processes, for example to check welds in car parts, verify correct electrode placement in batteries, detect soldering issues in electronics, and identify foreign particles in packaged food.

Human supervision

Klaus Gruber, Managing Director of Sioux Germany: ‘The condition of such a system can change, reducing the reliability of measurements, even if the process has previously been validated. This is widely known. In a fully automated production line, human supervision decreases, which increases the risk of unnoticed fault conditions and all the consequences that come with them.’

Serious safety issues

Unnecessarily rejecting and discarding products leads to costly production losses. Even more risky is the opposite scenario: components that do not meet quality standards pass inspection and end up in final products. In the worst case, this can lead to serious safety issues, such as short circuits or even fires in car batteries. Sioux’s CMX system resolves this problem.

The gap in monitoring

Advanced X-ray inspection systems are generally checked at fixed intervals using test phantoms, objects used to verify and calibrate the system. However, this interrupts production and offers no information between phantom measurements. Additional visual assessment by a human operator may be useful, but it is time-consuming and not all faults are detected, as some deviations are invisible to the human eye.

Recognizing deviations

Alexander Jung, Software Architect and X-ray technology specialist at Sioux Germany: ‘Typically, one component in an X-ray inspection system controls the source and detector parameters, another performs the reconstruction, and yet another detects anomalies and defects. Monitoring between these components is often missing. With Condition Monitoring X-ray (CMX), developed at our X-ray expertise centre in Erlangen, Sioux closes this gap. This enables fully automated and continuous quality control.’

Radically different

What makes CMX unique is the combination of conventional image analysis with a neural network approach in which smart algorithms and machine learning are used to detect and diagnose fault conditions in inspection systems. Sioux trained CMX’s neural network on simulated data, replicating dozens of fault scenarios, both individually and in combination. ‘With a real X-ray system, collecting such training data would have been extremely costly and time-consuming, if possible at all,’ says Jung. ‘Thanks to simulation, we could cover more faults and their root causes and develop a better system.’

Blind test

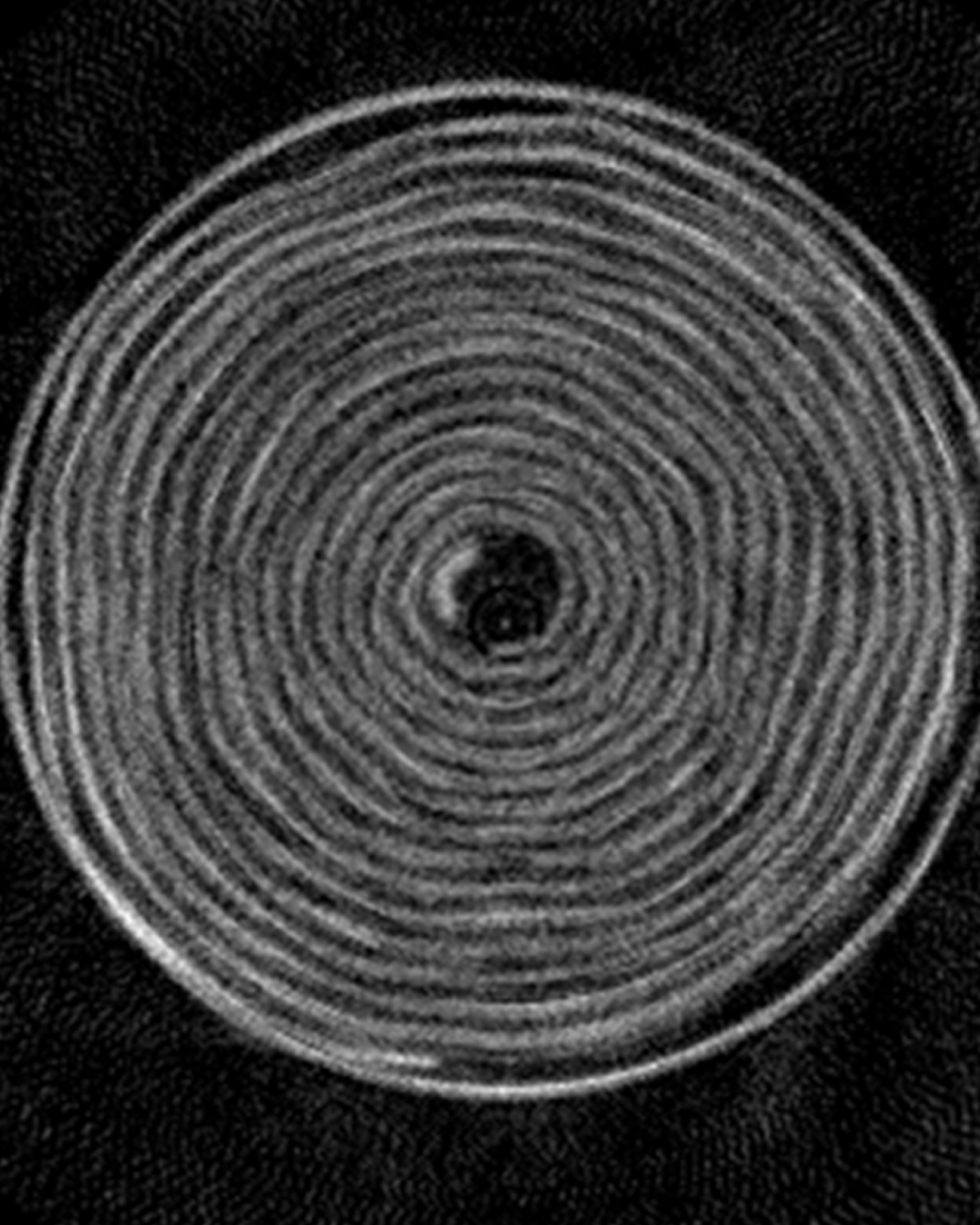

It has now been proven that CMX can detect defects such as noise, blurriness, and ring artefacts. In addition, the system can identify root causes such as decreased source energy and intensity, an enlarged focal spot, or misalignment and wear of the detector. Detecting additional defects and causes is continually being developed further. This pushes the boundaries of industrial quality assurance, as demonstrated when Sioux received a set of inspection images from a medtech client, without explanation, as a blind test, and asked to run CMX on them. Using CMX, deviations and defects were identified that the client had not yet noticed.

Easy integration

Gruber: ‘This immediately confirmed the strength of our solution. Thanks to our expertise in X-ray simulation, we can replicate clients’ systems and demonstrate that CMX can detect faults and their causes. In addition, our solution is designed for easy integration into existing production lines. It is an additional technology; replacing existing monitoring solutions is not necessary. It also uses already available data: 2D projections and 3D reconstructions. Implementation begins with a short feasibility study: evaluating the use case, analysing the data, and parameterising CMX. Follow-up options include integration into the inspection system, data visualization, a feedback loop with an operator, neural networks, and more.’

Product recalls

The benefits of CMX are significant, Gruber emphasises. Early fault detection reduces the number of false positives and false negatives, lowering both costs and risks. Manufacturers also gain immediate insight into the condition of their inspection systems, making it possible, for example, to order replacement parts in time. The effect is increased uptime, greater reliability, and a reduced likelihood of product recalls. In this way, CMX makes a demonstrable contribution to the return on investment of quality assurance programmes.

Looking ahead

CMX is already being integrated at several Sioux clients, including a car manufacturer and a medical equipment producer. Among other things, these integrations examine the added value for specific applications and optimize implementation in production lines. ‘From a technological perspective, we are fully ready for the market,’ says Jung. At the same time, CMX continues to evolve. The technology is not limited to X-ray inspection.

Optical cameras

Jung: ‘At its core, CMX is a data acquisition tool, broadly deployable for detecting deviations and defects in products. We are now also focusing on applications using other sensors, such as optical cameras. Predictive maintenance and additional measurements are also on the roadmap. The data required for this stems from new innovations. In addition, we are contributing to the standardization of methods and norms for X-ray inspection, for example within SensMonCT, a European research project focused on developing technology to automatically and continuously monitor and calibrate industrial CT scanners.’

Learning and growing

‘This is also what makes Sioux unique,’ Gruber adds. ‘The introduction of CMX marks a new step in X-ray inspection. We can develop such complex systems and make them work in practice by combining software, mathware, electronics, optics, and mechanics in one integrated approach. At the same time, we aim to learn and grow together, for example by combining client projects with our own research and participation in broader innovation programmes, to push technological boundaries and transform markets.’