A thorough knowledge of the properties of the relevant film material is not sufficient to be able to shape the film smoothly and seamlessly, as demonstrated by our first analysis. Complex 3D shapes such as helmets can be produced by laminating several layers of film on top of one another. The method used to date often led to undesirable creases, and as such, to unusable products.

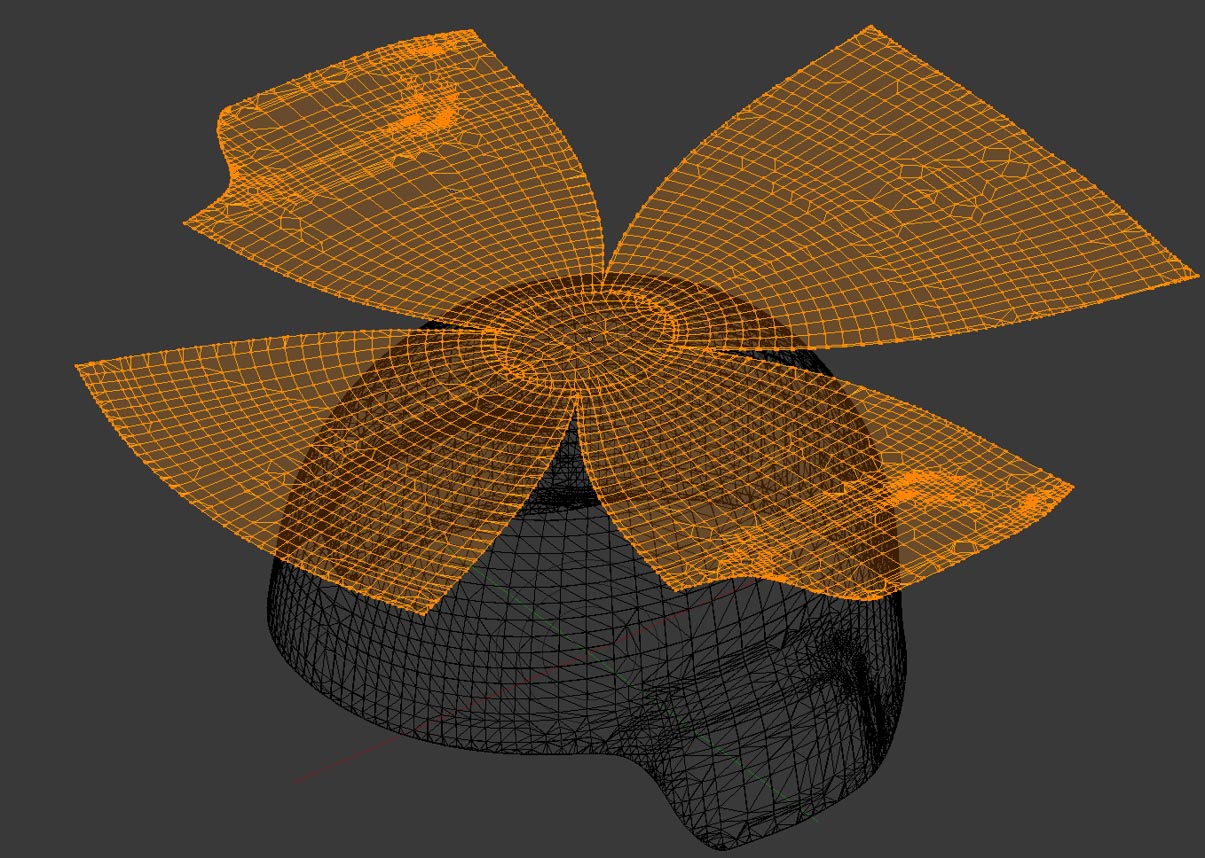

Sioux translated the practical problem to a numerical model and revealed the underlying issue. By cleverly combining mesh techniques and open source software for the modelling and animation of 3D computer graphics, we were able to display any 3D shape on 2D film so that it can be laminated, without creases, in the desired 3D shape.

Making helmets without folds and creases has been made possible. Furthermore, Sioux’s solution is generic and enables the manufacturer to effortlessly adapt the products to any new demands their customers might have.

Finite element modelling (FEM), Mesh optimization, Solid mechanic, Geometrical optimization, Strength optimization, 3D computer graphics.

Teijin Aramid is the global leader in aramid technology. Aramid fibres are man-made high-performance fibres that have high-tenacity, low-weight and high-impact resistance. This makes them suitable for high-performance applications, including ballistic protection, heat and chemical protection and applications for the oil and gas industries.